Precise Spares

Makes Machine Life Longer

We would like to introduce ourselves as acompany, serving textile people in the field of Computerised Electronic Chenille Machine with all its manufacturing facility and corporate office in Panipat City of Haryana State in India. With more than l7 years of Experience of Company's Directors in engineering, best C.N.C machines, Engineering design studio, skilled engineers, ontime delivery and best quality, company is moving fastly around the world through its agents in Iran, Egypt Turkey and brazil.

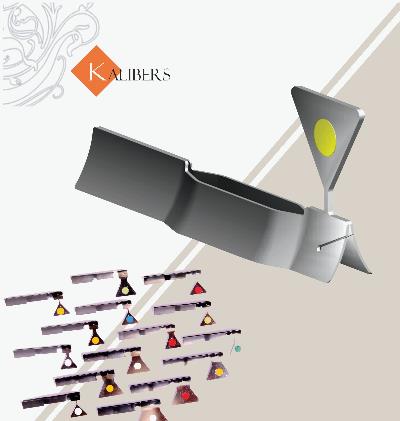

Operational Features : The chenille head is designed for the very less consumption of parts and to produce high quality of chenille yarn. Best is that there is no need of keys, L-keys and spanner by operator as all adjustments can be done with free hand. Blade assembly can be adjusted up-down and Yes left-right also precisely, thanks to this technology which gives perfect alignment to the blades of differentthickeness.

10th INDIA ITME 2016

We know how

to Engineering

Texo Manufacturing is committed to providing a superior quality service using the latest technology in CNC machining. The Leading technology allows for reduced project timelines and improved project accuracy through the use of high-performance, computer numerically controlled machinery. We manufacturer our spare parts by the help of CAD(Computer Added Design), CAM(Computer Aided Manufacturing), CNC(Computer Numerical Control) and VMC(Vertical Machining Center) in Panipat, HARYANA.

Few words about

Texo Engineering Works

High quality precision works enable us to export textile spare parts to Italy, Turkey, Usa, Brazil & other countries.

We Serving spare parts of all types Italian Chenille machines since 1997. We manufacturer Kaliber, Driver, Anti-Driver, Roller, Anti-Roller, Rotary Blades, Numetic Sharpening Machine, Universal Joint, Cutter Assembly, Capston Roller, Driver Arms, Kaliber Holder, Seprator Holder, Rings, Ring Travelors Etc.

Size availability in mm : 0.6, 0.7, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0 2.5, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 10.0

We have two types of SHARPENING STONES Ceremic type red 8: Diamond type with aluminium body. The red stones are economic in sharpening and prices and diamond types are best in long lasting sharpening with making rotary bladers life more longer.

DRIVERS are made of High Quality Tool steel. These are made on c.n.c turning machines with high accuracy keeping in mind that dimensions should not differ for 1st piece to next any one. Hardening and Tempering is done to make its working life for years. Knurling is done in two types i.e Fine Knurl (A) and Very Fine Knurl (B) Size availability is : T = 2.5, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0 mm (Can be developed as per requirement) T 2 = ll mm (Can be developed as per requirement)

ROTARY BLADES comes in different thickness, shapes and material. For example : All dimensions are in “mm” Outer Diameter Inner Diameter Thickness 100 22 8: 34 0.60 100 22 8: 34 0.80 100 22 8: 34 1.00 All above blades are made 0fHSS M2 Tool Steel, with very high precision, hardened and tempered to make yarn cutting application perfectly and smoothly. All blades are very Well inspected to flatness, hardening degree, edges and packed by expert people in the presence of quality manager.